Description

Efficient dredging

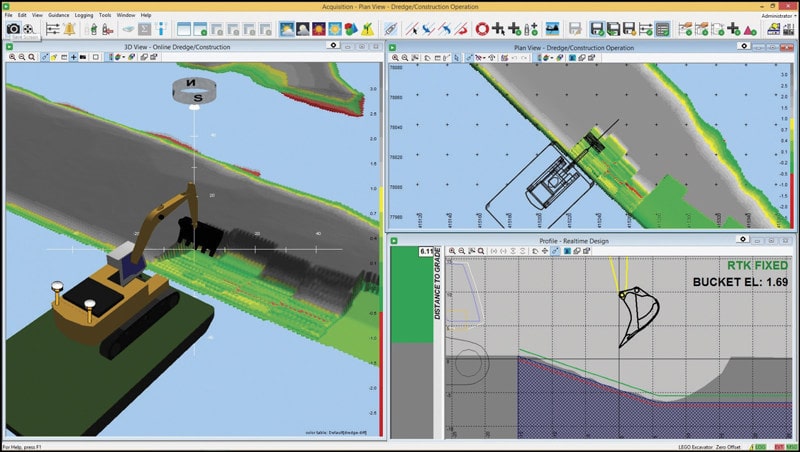

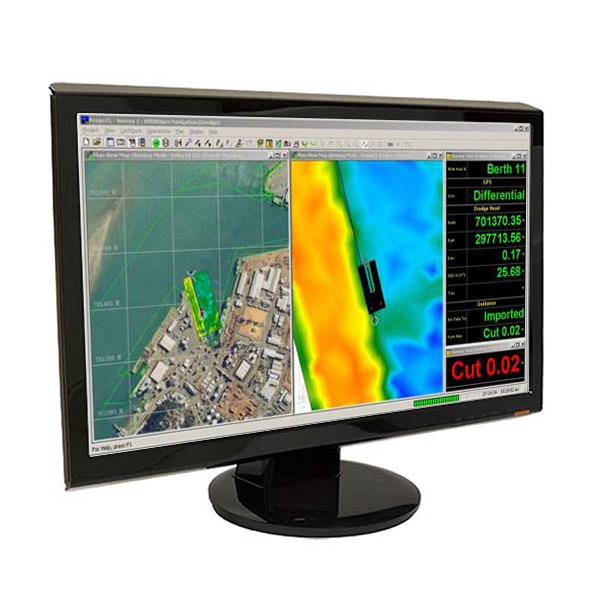

Trimble Marine Construction software for cutter suction dredger applications is a powerful tool to help dredge operators improve productivity and efficiency. The operator and tug captain have a real time view of the dredger with the plan and profile views displaying the vessel outline and the dredge head along with the surveyed surface, design and dredged depth.

Real-time visualization and monitoring

The software supports visualization and monitoring of the angle and position of the ladder and cutterhead. It also shows the absolute position of the dredge head in relation to the surveyed and any number of design surfaces. The working surface is updated with the dredged depths in real time and displayed in plan, profile and 3D views. Over-dredge and under-dredge tolerances can be set and are visible on the profile view of the dredge head.

Customizable interface

Multiple monitors, with independent layouts can be tailored to the needs of the dredge operator. A colour-coded plan view and 3D rendering highlights high and low spots. The surface Digital Terrain Model (DTM) is updated in real time registering the progress of the dredging work showing depth, differential and production models all updated according to progress of the cutter head.

Cumulative production calculation (via 3rd party sensor)

The cumulative production calculation and reporting feature helps monitor efficiency and progress. When the water density and product density are known, the sensor can calculate total production. This allows operators to focus on the task at hand and allow the software to report progress by runline, block or job. It also makes it easy for off-site project managers to track progress.