Description

Accurate placement

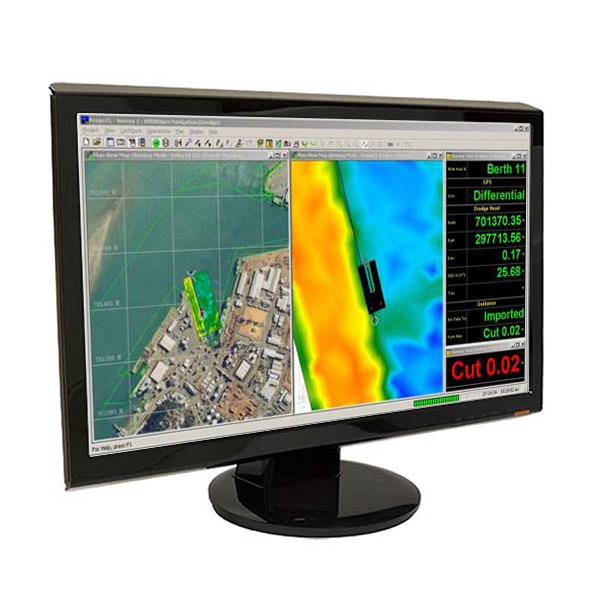

Trimble Marine Construction software for armour rock and block placement applications is a powerful tool to help construction contractors improve productivity and efficiency. The operator has a real time view of the excavator, crane and barge in plan and profile views. Profile displays show tool depth along with the surveyed and design depths.

Real time visualisation and monitoring

Real time views of the machine in plan and profile views display the block or grapple, design depths and colour-coded Digital Terrain Model (DTM). The DTM highlights the high and low spots relative to the design and is updated in real time, tracking the progress of the construction project. The surface is updated in real time based on the block or material placed and the material’s characteristics. The sonar option can scan after placement for a more precise surface updates and greater quality control.

Real time seafloor and design

Up/down indicators show the operator the exact distance to the design surface continuously. The software supports complex 3D designs.

Workflows

The software makes it easy to select block designs and monitor the block placement process. Block position is calculated by the crane’s position and measuring the angle and pay out of the hoisting wires. If the wire is not vertical due to tide or current, a laser can be added for improved positioning.

Customisable interface

Multiple monitors with independent layouts can be tailored to the needs of the operator. A colour-coded plan view and 3D view highlights surface high and low spots. The surface Digital Terrain Model (DTM) is updated in real time registering construction progress showing depth, differential and production models.